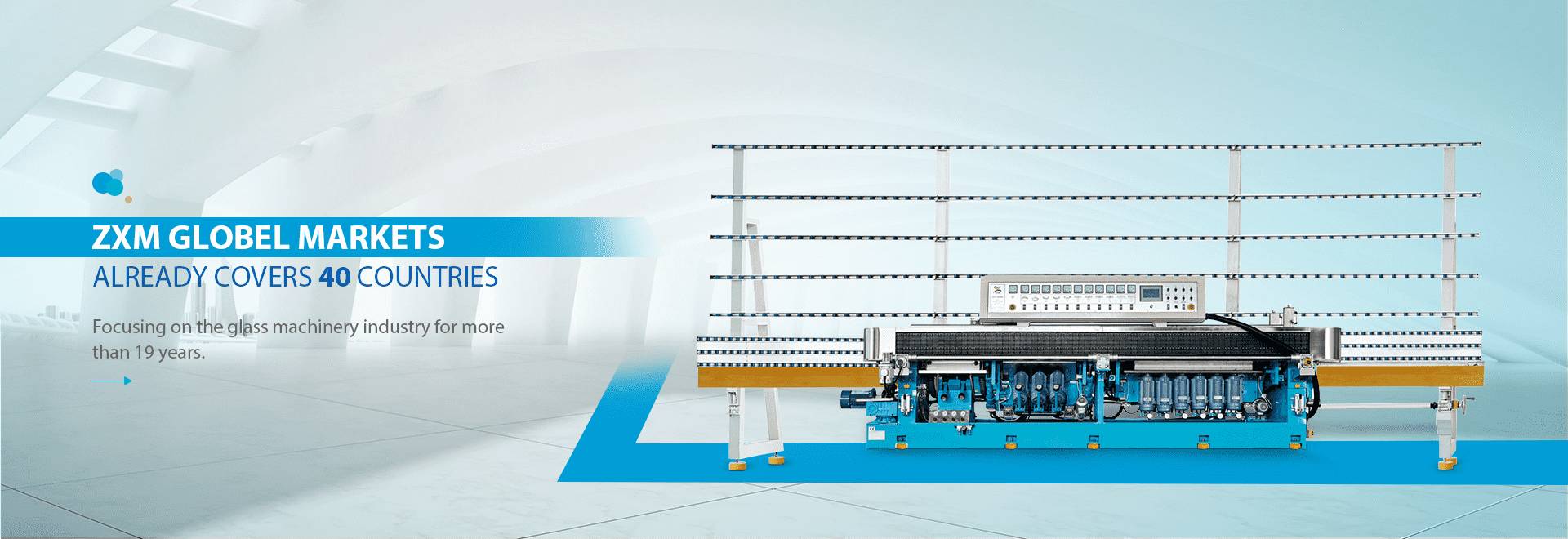

Welcome to our websites!

- Glass Edging Machine

- Glass Drilling Machine

- Glass Washing Machine

- Glass Beveling Machine

- Glass Sludge Dehydrator

- Glass Sandblasting Machine

- Glass Wave Beveling Machine

- Glass Double Edging Machine

- Glass Round Edge Grinding Machine

- Glass Variable Angle Edging Machine

- Shape Glass Edging/Beveling Machine

-

horizontal low-e glass washing machine air blade system

Structure Feature:

1.1 Main drive is gear drive, motor speed is controled by frequency inverter, digital display show speed and glass thickness. Roller Brush are drove by upper and lower motors with separate belt, which has smooth speed and long service life.

1.2 Metal plates of washing part and parts which contacts with water are made of stainless steel.

1.3 All transmitting rubber rollers of the machine are vulcanized rubber (They are forbidden to contact with acidic liquids.). -

10 motors automatical ball bearing heavy duty glass edging mitering machine

This machine has 6 motors which can process glass bottom edge and front arris(0-45 degree), with 2 motors for front seaming and 2 motor for rear seaming. This machine use BEARING CONVEYOR SYSTEM. It is suitable for small glass (40mmx400mm) and heavy glass (4mx4m) processing. The machine has a glass thickness protection mechanism. When wrong thickness glass is put in the machine, the machine will stop automatically. This protects the bearings from crushing. The machine adopt PLC control and operator interface. The working speed can be adjusted via the stepless regulator. The processed glass surface is very bright and smooth, approaching to the original glass surface. This machine is also featured by wide processing range and easy operation. -

11 motors automatical ball bearing variable angle glass edging mitering machine

This machine has 6 motors(No.1-No.6) which can process glass bottom edge and front arris(0-60 degree), 3 motors (No.7-No.9) which can process glass miter edge and also bottom edge, with 2 motors for rear seaming. All process is finished at one travel. To make flat edging/polishing, No.1-No.6 motors need to stay at ZERO degree and No.7-9 motor can be changed to 45 degree for front arris. To make miter and bottom edge, No.1-No.6 motors can be adjusted to the requested degree and turn No.7-No.9 motors to ZERO degree for bottom edge processing. This machine use BEARING CONVEYOR SYSTEM. It is suitable for small glass (40mmx40mm) and heavy glass (4mx4m) processing. -

15 motors automatical ball bearing variable angle glass edging mitering machine

The first section 6 motors(No.1-No.6) process glass bottom edge and front miter edge (0-60 degree), 2 motors (No.7-No.8) for back arris seaming and 2 motors (No.9-No.10) for front arris seaming. No.11.No.12 and No.13 motors are for bottom edge grinding and final polishing when No.1-No.6 motors for front miter processing. The last two wheels are for front and back arris polishing. All process is finished at one travel.

This machine use BEARING CONVEYOR SYSTEM. It is suitable for small glass (40mmx40mm) and heavy glass(4mx4m) processing. The top brackets structure can make conveyors running stably to work very small glass 40mm size. -

automatical chain system variable angle glass edging mitering machine

This machine can do normal flat edge polishing, it can also make miter edge of 0-45 degree. This machine use PLC control and touch panel operating system. The machine can run in automatic mode and manual mode. The front 4-6 motors can adjust angle from 0 degree to 45 degree for polishing bottom edge and miter edge. -

automatic physical centrifugal water treatment dehydrator

This machine will give a best solution for glass production industry. It can easily separate the glass powder created by edge processing, increase machine life time, reduce maintenance time, reduce water consumption and protect our precious earth.This sludge dehydrator adopts centrifugal technology. Barrel rotates at high speed, meanwhile muddy water pumped into the barrel by water pump and spray out by high speed centrifugal movement. Clean water flow back to the water tank. -

PLC controlled vertical glass sandblasting machine easy operation

The machine is controlled by the PLC, suitable for processing 5-30mm thickness of flat glass and steric pattern. Glass is conveyed by the belts, when glass arrive to the place for sandblasting, the guns which are drive by belt will move up-and-down and spurt out sand. The height and the width of sandblasting can be adjusted according to the requirement. The advantages of the belts are stable transmission, high efficiency and easy maintenance. The drive structure of the sandblasting gun is outside the machine which make benefited to a long period normal working and daily maintenance. The machine adopts the PLC for controlling, which brings easy operation and exploration the glass position automatically when sandblasting. -

3 motors round edge OG edging machine economic

The machine produce round edge, OG edge, and other profile edge on flat glass. Front rail is driven by handwheel and move in parallel to adapt to different glass thickness. Working speed is adjustable through speed regulator. It is featured by compact structure, convenient operation, low price and low processing cost.

-

6 motors round edge OG edge most popular glass machine

The machine can produce round edge, OG edge, and other profile edge on flat glass. Front conveyor can be moved in parallel to adapt to different glass thickness. The two front seaming wheels can remove arris of glass, which reduce the work of rear peripheral wheels, prolong the life time of peripheral wheel and increase working speed. -

chain system automatic glass flat edge polishing machine puenmatic

This machine use PLC control and touch panel operating system. It perform flat edge polishing, the pneumatic polishing system makes the machine more friendly for operation, the glass finish is super ideal. The machine can run in automatic mode and manual mode. Conveyor use chain transmitting system, working speed is adjustable through speed regulator. -

11 motor chain system digital 45 degree glass edging machine

The machine is designed for grinding/polishing bottom edge and 45 degree mite edge of flat glass. Four wheels work the bottom edge and four wheels work the miter edge at the same time. Both two edges have a very good finish. This is a high performance/price ratio machine. The four wheels for miter edge is fixed on the machine base, there is no vibration. Conveyor adopts chain transmitting system. Working speed is adjustable through speed regulator. Working speed and glass thickness appear on digital display. -

13 motor chain system digital 45 degree glass edging mitering machine

This machine has 6 motors fixed in 45 degree, which can be used to make 45 degree miter.

The machine is designed for grinding/polishing flat edge and 45 degree miter edge, with back arris grinding.

Conveyor adopts chain transmitting system consisting of special stretchy rubber pad.

Front rail is driven by motors and move in parallel to adapt to different glass thickness.